Titanium Valve

◆ Titanium is a new type of metal. The performance of titanium is related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purest titanium iodide impurity content does not exceed 0.1%, but its strength is low and its plasticity is high. The properties of 99.5% industrial pure titanium are: density ρ = 4.5g / cm3, melting point 1725 ° C, thermal conductivity λ = 15.24W / (mK), tensile strength σb = 539MPa, elongation δ = 25%, section Shrinkage ψ = 25%, elastic modulus E = 1.078 × 105MPa, hardness HB195.

◆ The density of titanium alloy is generally about 4.51g / cm3, which is only 60% of steel. The density of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength / density) of the titanium alloy is much greater than that of other metal structural materials. See Table 7-1, which can produce parts with high unit strength, good rigidity, and light weight. The aircraft engine components, skeleton, skin, fasteners and landing gear are all made of titanium alloy.

◆ Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is far better than that of stainless steel. It is particularly resistant to pitting, acid, and stress corrosion; organic objects such as alkali, chloride, and chlorine, nitric acid, and sulfuric acid Etc. Have excellent corrosion resistance. However, titanium has poor resistance to reducing oxygen and chromium salt media.

| Good low temperature performance |

◆ Titanium alloys can maintain their mechanical properties at low and ultra-low temperatures. Low temperature properties, titanium alloys with very low interstitial elements, such as TA7, can still maintain a certain degree of plasticity at -253 ° C. Therefore, titanium alloy is also an important low temperature structural material.

| Design Standard+ |

◆ Design: API 609, API6D,API602 / B16.34 / BS5352 / API600 / BS1873/ BS 1868/ API 594

◆ Face to face: API609 / ISO5752 / DIN F4 /EN558 / API6D / ASME16.10

◆ Flange end: ASME B16.5 / ASME B16.47 / EN1092-1 / GOST 12815 / Gost 33259 /MSS-SP44

◆ Butt-welding end: ASME B16.25

◆ Test: API598 / API6D

| Technical Specification+ |

◆ Size: 1/2”~80”(DN15~DN2000)

◆ Class: 150LB ~ 2500LB / PN6 ~ PN420

◆ Connection: Double flange / Butt weld / Lug / Wafer

◆ Operation: Worm Gear / Pneumatic actuator / Electric actuator

◆ Temperature: 1500℃

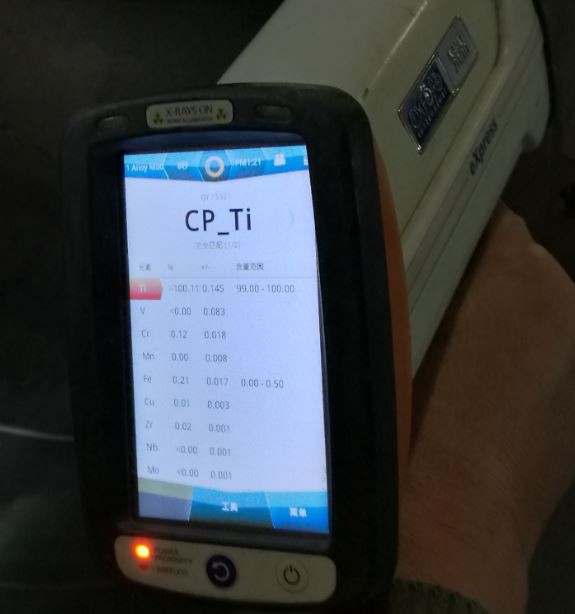

| Chemical composition + |

| Total corrosion |

◆ titanium has excellent corrosion resistance in oxidizing and neutral media. at this time, the oxide film on the titanium surface can exist stably, and can recover quickly after being destroyed for some reasons. In strongly reducing acids, titanium oxide films are easily dissolved and therefore not corrosion resistant. in some dilute reducing acids with low temperature, titanium also has a certain corrosion resistance, especially when the reducing acid contains oxidizing metal ions, oxygen and other oxidants, titanium also has better corrosion resistance.

The corrosion resistance of titanium in the main medium is described below, respectively.

1. nitric acid

titanium has excellent corrosion resistance in various concentrations of nitric acid below boiling point.

2. sulfuric acid

titanium is not corrosion resistant in 10%~98% concentration of sulfuric acid and can only be used in 5% dissolved oxygen sulfuric acid at room temperature. At 100℃, titanium can only retain pure titanium in 0.2 sulfuric acid.

3. sulfuric acid

titanium has moderate corrosion resistance in hydrochloric acid. Generally, industrial pure titanium can be used in hydrochloric acid at room temperature ,7.5%;60℃,3%;100℃,0.5%. There have also been reports of lower concentrations that could be used.

4. phosphoric acid

Titanium can be used in 35℃,30%;60℃,10%;100℃, less than 3% phosphoric acid. the corrosion resistance of titanium in phosphoric acid can be improved if Fe+3, CuFe+2, AgFe+1,2 and nitric acid are contained in the medium.

5. other inorganic acids

titanium is not corrosion resistant in hydrofluoric acid and can not be used in acid fluoride solutions. Titanium is resistant to corrosion in boric acid, chromic acid; it can be used in some hydroiodic acid, hydrobromic acid; it is generally not used in fluorobic acid, fluorosilicic acid. titanium can be used for mixed acid of 60℃,10% sulfuric acid and 90% nitric acid; mixed acid of boiling 1% hydrochloric acid and 5% nitric acid as well as in room temperature Wang Shui.

6. bases and salts

titanium is resistant to most lye. titanium is completely resistant to corrosion in various concentrations of barium hydroxide, calcium hydroxide, magnesium hydroxide, sodium hydroxide and potassium hydroxide solutions at room temperature and can not be used in boiling sodium hydroxide, potassium hydroxide solutions. When the alkali solution contains free chlorine, titanium can resist corrosion. ammonia in the base will aggravate the corrosion of titanium.

7. water

Titanium has excellent corrosion resistance in tap water and river water even if the temperature is up to 300℃. At the 120℃ High corrosion resistance in seawater; point corrosion and crevice corrosion may occur if the temperature is increased.

8. organic matter

Titanium has excellent corrosion resistance to all organic acids except ant acid, oxalic acid and concentrated citric acid.

9. chlorine, chlorides and other halogens

◆ Titanium can react violently in dry chlorine gas to form titanium tetrachloride, and it is in danger of ignition. Because titanium tetrachloride can react with water to form titanium hydroxide, titanium has good corrosion resistance in wet chlorine. The water content needed for the purification of titanium in chlorine gas is related to the temperature, flow rate, pressure and damage of titanium surface film. generally, the minimum water content required to maintain titanium purification is 0.01%~0.05%. usually in order to ensure safe production, when chlorine gas is in contact with titanium equipment, the water content in chlorine gas is actually controlled at about 0.3%, even sometimes up to 1.5%.

10. Urea ammonium formate solution

The corrosion rate of titanium in high temperature and high pressure urea ammonium formate solution is generally 0.01 mm/a, which is one quantity pole lower than that of 00 Cr 17Ni 14Mo 2 stainless steel. the maximum temperature allowed for titanium to maintain corrosion resistance can reach 205~210℃, while stainless steel can only withstand corrosion below 190~195.

11. Gas

◆ titanium can be oxidized. dense oxide film is formed below 300℃, and oxide film formed below 700℃ can improve corrosion resistance. When the temperature is higher, the oxide film becomes brittle and easily exfoliated into oxide skin. as structural materials, titanium can be used below 425℃ in air; as non-structural materials, it can be used below 535℃.

◆ Titanium has excellent corrosion resistance in sulfur dioxide, hydrogen sulfide, ammonia gas and oceanic atmosphere.

◆ At more than 300℃, hydrogen can obviously enter titanium, in addition to the physical infiltration of hydrogen in titanium to cause hydrogen embrittlement of titanium, hydrogen can also be combined with titanium to form hydrogen embrittlement of hydride type. increasing the hydrogen partial pressure will aggravate the hydrogen embrittlement of titanium. When the water content in hydrogen exceeds 2%, it can effectively prevent hydrogen infiltration. anodized surface treatment can improve the hydrogen resistance of titanium.

◆ local corrosion

Compared with stainless steel, nickel-based alloy, copper alloy and aluminum alloy, industrial pure titanium has high resistance to local corrosion, excellent resistance to point corrosion, and is insensitive to intergranular corrosion, stress corrosion, corrosion fatigue and so on, which can only occur in very few media. titanium, like other purified metals, is more prone to crevice corrosion and can also produce selective corrosion and contact corrosion in very few cases. As long as we pay attention to the use conditions of titanium and take appropriate measures, the local corrosion of titanium can be avoided mostly.

◆ Corrosion resistant titanium alloy

In the case that industrial pure titanium can not meet the corrosion requirements, corrosion resistant titanium alloy can be used.

Hot Tags: titanium valve, China, manufacturers, factory, customized, wholesale, price, cheap, in stock, for sale, free sample, corrosion resistant special material valve, wafer type special material valve, full bore special material valve, special material valve supplier, viton seated special material valve, special material diaphragm valve

Send Inquiry