As a seasoned supplier of butterfly valves, I've encountered numerous inquiries regarding the flow coefficient of these essential components. The flow coefficient, often denoted as Cv, is a critical parameter that quantifies a valve's ability to pass fluid. In this blog, I'll delve into the concept of the flow coefficient of a butterfly valve, its significance, factors influencing it, and how it relates to the performance of our products.

Understanding the Flow Coefficient (Cv)

The flow coefficient (Cv) is defined as the number of US gallons per minute (GPM) of water at 60°F that will flow through a valve with a pressure drop of 1 psi across the valve. It serves as a standardized measure to compare the flow capacity of different valves. A higher Cv value indicates that a valve can pass more fluid under the same pressure conditions.

For butterfly valves, the flow coefficient is determined through rigorous testing in accordance with industry standards. These tests involve measuring the flow rate of a fluid (usually water) through the valve at various pressure differentials. The data collected is then used to calculate the Cv value, which is typically provided in the valve's technical documentation.

Significance of the Flow Coefficient

The flow coefficient is a crucial factor in valve selection and system design. It helps engineers and designers determine the appropriate valve size and type for a specific application. By knowing the required flow rate and pressure drop of a system, they can select a butterfly valve with a Cv value that meets or exceeds these requirements.

In addition to valve selection, the flow coefficient also affects the overall performance of a system. A valve with an insufficient Cv value may cause excessive pressure drop, leading to reduced flow rates and increased energy consumption. On the other hand, a valve with an overly large Cv value may result in poor flow control and instability.

Factors Influencing the Flow Coefficient of a Butterfly Valve

Several factors can influence the flow coefficient of a butterfly valve. These include:

- Valve Size: Larger valves generally have higher Cv values than smaller valves, as they can accommodate a greater flow rate.

- Disc Design: The shape and configuration of the valve disc can significantly affect the flow coefficient. For example, a streamlined disc design can reduce turbulence and improve flow efficiency, resulting in a higher Cv value.

- Valve Opening: The degree to which the valve is opened also affects the flow coefficient. As the valve opening increases, the flow coefficient generally increases as well. However, at a certain point, the increase in flow coefficient may become less significant due to factors such as valve seat design and fluid dynamics.

- Fluid Properties: The properties of the fluid being handled, such as viscosity and density, can also impact the flow coefficient. For example, a more viscous fluid may require a larger valve or a higher pressure drop to achieve the same flow rate as a less viscous fluid.

Flow Coefficient and Our Butterfly Valve Products

At our company, we understand the importance of the flow coefficient in valve performance. That's why we offer a wide range of butterfly valves with different Cv values to meet the diverse needs of our customers. Our valves are designed and manufactured using advanced technology and high-quality materials to ensure optimal flow performance and reliability.

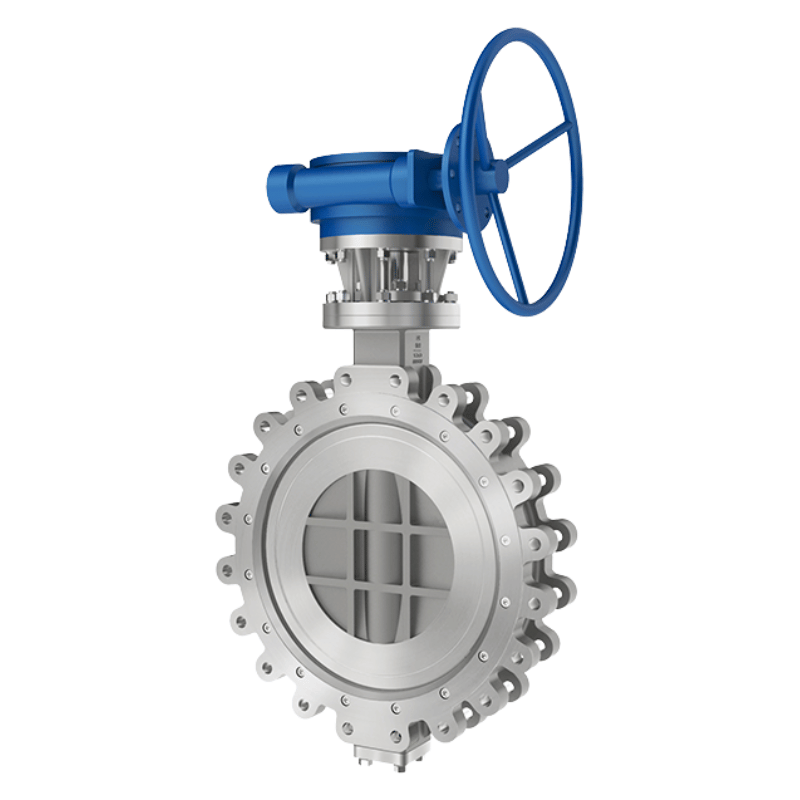

One of our popular products is the Double Offset Butterfly Valve. This valve features a unique double offset design that provides excellent sealing performance and low torque operation. It also has a high flow coefficient, making it suitable for applications where high flow rates and low pressure drop are required.

Another product in our portfolio is the Special Material Ball Valve. This valve is made from special materials that offer superior corrosion resistance and durability. It has a high Cv value and can handle a wide range of fluids, including corrosive and abrasive media.

We also offer the 2 Eccentric Butterfly Valve, which is designed for applications where precise flow control is required. This valve has a 2 eccentric design that provides a tight seal and excellent flow characteristics. It also has a high Cv value, making it suitable for both on-off and throttling applications.

Conclusion

The flow coefficient is a critical parameter that plays a significant role in the performance of a butterfly valve. By understanding the concept of the flow coefficient and its influencing factors, engineers and designers can select the right valve for their applications and ensure optimal system performance.

As a leading supplier of butterfly valves, we are committed to providing our customers with high-quality products that meet their specific needs. Our valves are designed and manufactured to the highest standards, and we offer a comprehensive range of Cv values to ensure that you can find the right valve for your application.

If you have any questions about the flow coefficient of our butterfly valves or need assistance in selecting the right valve for your application, please don't hesitate to contact us. Our team of experts is always ready to help you make the best decision for your project.

References

- Crane Co., "Flow of Fluids Through Valves, Fittings, and Pipe," Technical Paper No. 410, 1988.

- International Society of Automation (ISA), "Flow Measurement Handbook: Industrial Designs and Applications," 2nd Edition, 2003.

- Valve Manufacturers Association of America (VMAA), "Valve Glossary," 2015.