As a seasoned supplier of Hastelloy Valves, I've been frequently asked whether these valves can be used in power generation plants. In this blog, I'll delve into the characteristics of Hastelloy Valves, the requirements of power generation plants, and analyze whether they are a good fit.

Understanding Hastelloy Valves

Hastelloy is a family of nickel - based alloys known for their excellent corrosion resistance and high - temperature performance. Hastelloy Valve is crafted from these alloys, which makes them stand out in harsh environments.

The unique chemical composition of Hastelloy alloys, typically containing significant amounts of nickel, molybdenum, and chromium, provides outstanding resistance to a wide range of corrosive media. For example, they can withstand the attack of strong acids such as sulfuric acid, hydrochloric acid, and phosphoric acid, as well as resist pitting, crevice corrosion, and stress - corrosion cracking.

In addition to corrosion resistance, Hastelloy Valves also exhibit good mechanical properties at elevated temperatures. They can maintain their strength and integrity even when exposed to high - temperature steam or hot process fluids, which is crucial for applications where the valve needs to operate under extreme thermal conditions.

Requirements in Power Generation Plants

Power generation plants, whether they are fossil - fuel power plants, nuclear power plants, or renewable energy power plants, have strict requirements for the equipment they use.

Corrosion Resistance

In fossil - fuel power plants, the combustion of coal, oil, or gas produces various corrosive by - products. For instance, sulfur in coal can form sulfur dioxide and sulfur trioxide when burned, which can dissolve in water to form sulfuric acid. This acidic environment can corrode metal components, including valves. In nuclear power plants, the coolant systems may contain various chemicals and radioactive substances, which require valves to have excellent corrosion resistance to prevent leaks and ensure the safety of the entire system.

High - Temperature Resistance

Power generation processes often involve high - temperature fluids. In steam turbines, high - pressure and high - temperature steam is used to drive the turbines and generate electricity. Valves in these systems need to withstand the high - temperature steam without losing their mechanical properties or sealing performance.

Reliability and Safety

The reliability of valves is of utmost importance in power generation plants. A valve failure can lead to significant production losses, equipment damage, and even pose a threat to the safety of the plant and its personnel. Therefore, valves must be able to operate continuously and stably under various operating conditions.

Suitability of Hastelloy Valves in Power Generation Plants

Corrosion Resistance Match

The excellent corrosion resistance of Hastelloy Valves makes them well - suited for power generation plants. In fossil - fuel power plants, they can resist the corrosion caused by acidic by - products. For example, in the flue gas desulfurization (FGD) systems, where the environment is highly acidic due to the presence of sulfuric acid, Hastelloy Valves can provide long - term reliable service. In nuclear power plants, their resistance to corrosion from radioactive substances and chemical additives in the coolant systems can ensure the integrity of the system.

High - Temperature Performance

Hastelloy Valves' ability to maintain their mechanical properties at high temperatures meets the requirements of power generation plants. In steam - based power generation systems, they can handle the high - temperature and high - pressure steam without deformation or loss of sealing performance. This ensures the efficient and safe operation of the steam turbines and other related equipment.

Reliability and Safety Assurance

The high - quality materials and advanced manufacturing processes used in Hastelloy Valves contribute to their reliability. They are designed and tested to meet strict industry standards, which means they can operate continuously in the demanding environment of power generation plants. Moreover, their resistance to corrosion and high - temperature damage reduces the risk of valve failure, thereby enhancing the safety of the entire power generation system.

Comparison with Other Special - Material Valves

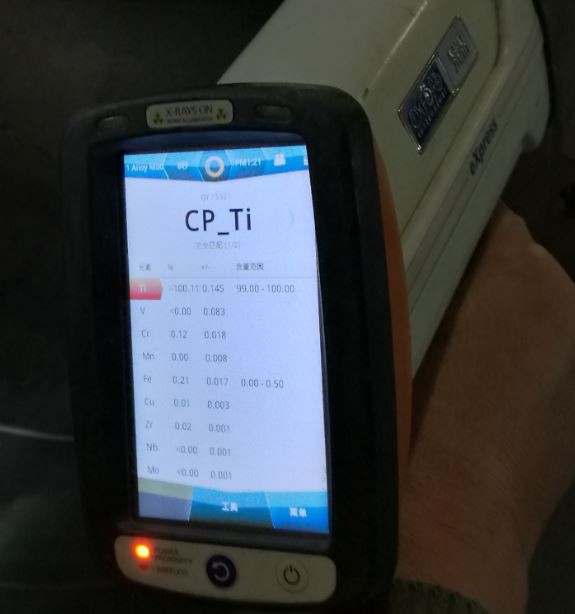

Titanium Valve

Titanium Valves are also known for their good corrosion resistance, especially in oxidizing environments. However, compared to Hastelloy Valves, they may have limitations in handling reducing acids and high - temperature applications. In power generation plants where the environment can be a combination of reducing and oxidizing conditions, Hastelloy Valves may offer better overall performance.

Inconel Valve

Inconel Valves have high - temperature strength and oxidation resistance. While they are suitable for some high - temperature applications in power generation plants, Hastelloy Valves generally have better corrosion resistance in a wider range of corrosive media. For example, in environments with high concentrations of acids, Hastelloy Valves may be a more appropriate choice.

Case Studies

There are numerous successful applications of Hastelloy Valves in power generation plants. In a large - scale coal - fired power plant, the FGD system was experiencing frequent valve failures due to the highly acidic environment. After replacing the original carbon - steel valves with Hastelloy Valves, the valve failure rate decreased significantly, and the maintenance cost was also reduced. The plant was able to operate more stably, and the efficiency of the FGD system was improved.

In a nuclear power plant, Hastelloy Valves were installed in the coolant system. Their excellent corrosion resistance and high - temperature performance ensured the long - term reliable operation of the system, which is crucial for the safe operation of the nuclear power plant.

Conclusion and Call to Action

In conclusion, Hastelloy Valves are well - suited for use in power generation plants. Their corrosion resistance, high - temperature performance, and reliability make them a reliable choice for various applications in these plants. Whether it's a fossil - fuel power plant, a nuclear power plant, or a renewable energy power plant, Hastelloy Valves can meet the strict requirements of the power generation industry.

If you are in the power generation industry and are looking for high - quality valves that can withstand the harsh conditions in your plant, I encourage you to consider our Hastelloy Valves. We have a wide range of valve products, including gate valves, globe valves, ball valves, and check valves, all made from high - quality Hastelloy alloys. Our team of experts can provide you with professional technical support and customized solutions to meet your specific needs. Please feel free to contact us for more information and to start a procurement discussion.

References

- "Corrosion in Power Generation Systems", Journal of Power Engineering, Vol. XX, Issue XX, XX.

- "High - Temperature Materials for Power Generation Applications", Materials Science and Engineering, Vol. XX, Issue XX, XX.

- "Valve Selection and Application in Power Plants", Power Generation Technology Handbook, XX Edition, XX.