In the complex ecosystem of refrigeration systems, safety valves play a crucial role in maintaining the integrity and safety of the entire setup. As a trusted safety valve supplier, I've witnessed firsthand how these components can make or break a refrigeration system. In this blog post, I'll delve into the intricacies of how safety valves function in a refrigeration system, their importance, and the different types available.

The Basics of a Refrigeration System

Before we dive into the role of safety valves, let's briefly understand the fundamentals of a refrigeration system. A typical refrigeration system consists of four main components: a compressor, a condenser, an expansion valve, and an evaporator. The compressor compresses the refrigerant gas, raising its pressure and temperature. The high-pressure gas then flows into the condenser, where it releases heat and condenses into a liquid. The liquid refrigerant passes through the expansion valve, which reduces its pressure and temperature. Finally, the low-pressure liquid enters the evaporator, where it absorbs heat from the surrounding environment and evaporates back into a gas. This cycle repeats continuously, removing heat from the refrigerated space and maintaining a low temperature.

The Role of Safety Valves in a Refrigeration System

Safety valves are essential components in a refrigeration system, designed to protect the system from overpressure situations. Overpressure can occur due to various reasons, such as a blockage in the refrigerant flow, a malfunctioning compressor, or an excessive heat load. If the pressure in the system exceeds the safe operating limit, it can cause serious damage to the equipment, including leaks, ruptures, and even explosions. Safety valves act as a fail-safe mechanism, automatically opening when the pressure reaches a predetermined set point and releasing the excess pressure to the atmosphere or a safe discharge location. This helps to prevent catastrophic failures and ensures the safety of the system and its operators.

How Safety Valves Work

Safety valves operate based on a simple yet effective principle: the balance between the inlet pressure and the spring force. The valve consists of a valve seat, a disc, and a spring. The disc is held against the valve seat by the spring force, preventing the flow of refrigerant. When the pressure in the system exceeds the set point, the force exerted by the inlet pressure overcomes the spring force, causing the disc to lift off the valve seat and open the valve. The excess pressure is then released through the valve outlet, reducing the pressure in the system. Once the pressure drops below the set point, the spring force closes the valve, stopping the flow of refrigerant.

Types of Safety Valves Used in Refrigeration Systems

There are several types of safety valves used in refrigeration systems, each with its own unique features and applications. Some of the most common types include:

- Spring-Loaded Safety Valves: These are the most widely used type of safety valves in refrigeration systems. They are simple in design, reliable, and cost-effective. Spring-loaded safety valves are available in various sizes and pressure ratings, making them suitable for a wide range of applications.

- Pilot-Operated Safety Valves: Pilot-operated safety valves are more complex than spring-loaded safety valves but offer higher accuracy and faster response times. They consist of a main valve and a pilot valve. The pilot valve senses the pressure in the system and controls the opening and closing of the main valve. Pilot-operated safety valves are often used in high-pressure and high-capacity refrigeration systems.

- Thermal Safety Valves: Thermal safety valves are designed to protect the system from overheating. They operate based on the principle of thermal expansion, opening when the temperature of the refrigerant exceeds a predetermined set point. Thermal safety valves are commonly used in refrigeration systems that are exposed to high temperatures or in applications where there is a risk of refrigerant overheating.

Selecting the Right Safety Valve for Your Refrigeration System

Choosing the right safety valve for your refrigeration system is crucial to ensure its proper functioning and safety. When selecting a safety valve, you need to consider several factors, including:

- System Pressure and Temperature: The safety valve must be rated for the maximum operating pressure and temperature of the refrigeration system.

- Flow Capacity: The safety valve must have a sufficient flow capacity to handle the maximum flow rate of the refrigerant in the system.

- Refrigerant Type: Different refrigerants have different properties, such as pressure, temperature, and corrosiveness. The safety valve must be compatible with the refrigerant used in the system.

- Installation Location: The safety valve must be installed in a location that allows for easy access and maintenance. It should also be installed in a way that ensures proper drainage and prevents the accumulation of moisture.

Our Safety Valve Offerings

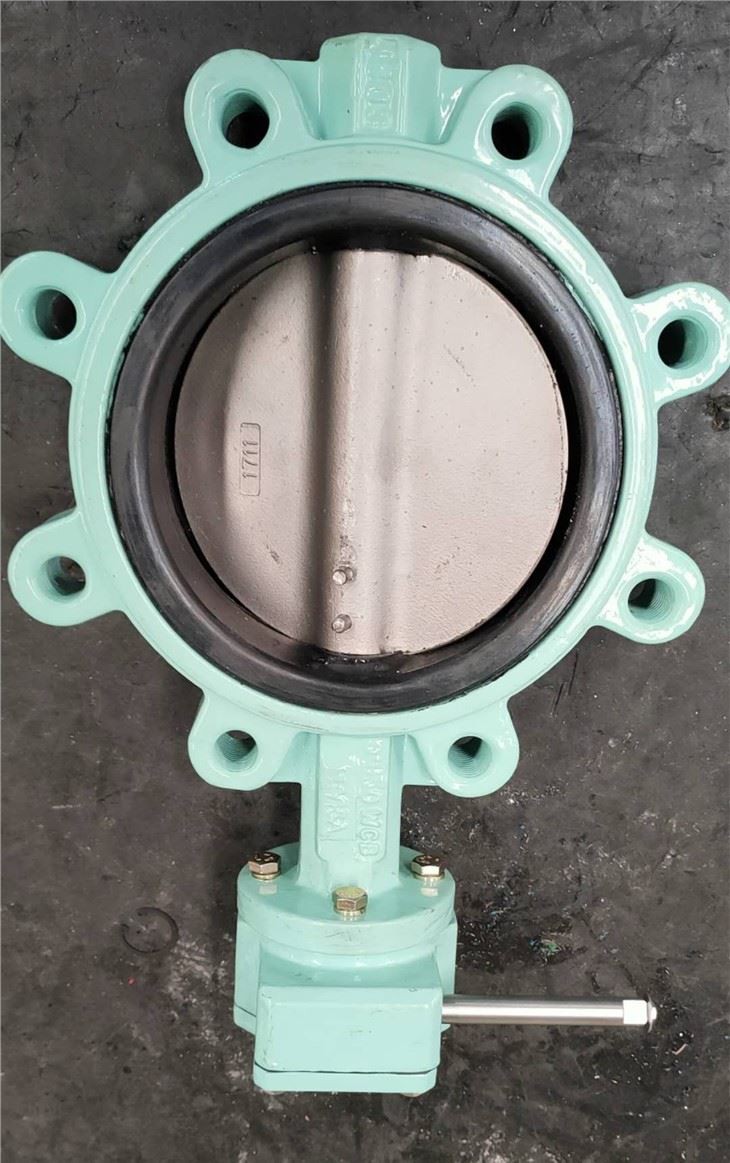

As a leading safety valve supplier, we offer a wide range of high-quality safety valves for refrigeration systems. Our valves are designed and manufactured to meet the highest industry standards and are available in various sizes, pressure ratings, and materials. We also offer custom solutions to meet the specific requirements of our customers. Some of our popular products include the Triple Offset Multilever Butterfly Valve, the Centerl Line Butterfly Valve, and the Newlotoke High Performance Butterfly Valve Catalogue.

Importance of Regular Maintenance and Testing

Regular maintenance and testing of safety valves are essential to ensure their proper functioning and reliability. Over time, safety valves can become clogged, corroded, or damaged, which can affect their performance. It is recommended to have the safety valves inspected, tested, and maintained at least once a year by a qualified technician. This includes checking the valve for leaks, verifying the set point, and ensuring that the valve opens and closes properly. Regular maintenance and testing can help to identify potential problems early on and prevent costly breakdowns and safety hazards.

Conclusion

Safety valves are critical components in a refrigeration system, providing essential protection against overpressure situations. By understanding how safety valves work and the different types available, you can select the right valve for your system and ensure its proper functioning and safety. As a safety valve supplier, we are committed to providing our customers with high-quality products and excellent service. If you have any questions or need assistance in selecting the right safety valve for your refrigeration system, please don't hesitate to contact us. We look forward to working with you to meet your safety valve needs.

References

- ASHRAE Handbook - Refrigeration. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.

- ISO 4126 - Safety valves. International Organization for Standardization.

- PED - Pressure Equipment Directive. European Union.