Hey there! As a Monel valve supplier, I've seen my fair share of issues that customers face, and one of the most common and troublesome ones is water hammer. In this blog, I'm gonna walk you through what water hammer is, why it's a big deal for Monel valves, and most importantly, how you can prevent it.

What is Water Hammer?

You know that sudden thud or bang you sometimes hear in your pipes? That's water hammer in action. It's a hydraulic shock that occurs when there's a sudden change in the flow rate of water in a pipeline. This change can be caused by things like quickly closing a valve, a pump starting or stopping abruptly, or even a sudden change in the water pressure.

When the flow of water is suddenly stopped, the kinetic energy of the moving water has to go somewhere. It gets converted into pressure waves that travel through the pipes at high speed. These pressure waves can cause a lot of damage, not just to the pipes themselves but also to the valves and other components in the system.

Why is Water Hammer a Problem for Monel Valves?

Monel valves are known for their excellent corrosion resistance, high strength, and good ductility. They're used in a wide range of applications, from chemical processing to marine environments. But even these tough valves aren't immune to the effects of water hammer.

The pressure waves created by water hammer can cause excessive stress on the Monel valves. This can lead to things like valve seat damage, which can cause leaks. Over time, the repeated stress can also lead to fatigue cracking in the valve body, reducing its lifespan and potentially causing a complete failure of the valve.

How to Prevent Water Hammer in Monel Valves

1. Use Slow-Closing Valves

One of the simplest ways to prevent water hammer is to use slow-closing valves. Instead of closing the valve all at once, a slow-closing valve gradually reduces the flow rate of water over a period of time. This gives the water in the pipeline a chance to slow down gradually, reducing the sudden change in flow rate and minimizing the pressure waves.

There are different types of slow-closing valves available, and you can choose the one that best suits your application. Some valves have a built-in mechanism that controls the closing speed, while others can be adjusted externally.

2. Install Surge Tanks

Surge tanks are another effective way to prevent water hammer. These tanks are connected to the pipeline and act as a buffer, absorbing the excess pressure created by the pressure waves. When the pressure in the pipeline increases due to water hammer, the water flows into the surge tank, reducing the pressure in the pipeline.

Surge tanks come in different sizes and designs, and you need to make sure that you choose the right one for your system. The size of the surge tank depends on factors like the flow rate of water in the pipeline, the pressure of the system, and the length of the pipeline.

3. Check and Maintain Your Piping System

A well-maintained piping system is less likely to experience water hammer. You should regularly check your pipes for any signs of damage, such as leaks, corrosion, or blockages. Leaky pipes can cause a sudden change in the flow rate of water, which can trigger water hammer.

Also, make sure that your pipes are properly supported. Loose or poorly supported pipes can vibrate when the pressure waves pass through them, increasing the risk of damage. You can use pipe hangers and supports to keep your pipes in place and reduce the vibrations.

4. Avoid Abrupt Pump Starts and Stops

If you're using pumps in your system, it's important to avoid starting and stopping them abruptly. When a pump starts suddenly, it can create a surge in the water flow, while a sudden stop can cause a reverse flow and pressure waves.

To prevent this, you can use soft-start and soft-stop controls for your pumps. These controls gradually increase or decrease the speed of the pump, reducing the sudden change in the water flow rate and minimizing the risk of water hammer.

5. Install Pressure Relief Valves

Pressure relief valves are designed to open when the pressure in the pipeline exceeds a certain limit. They release the excess pressure, preventing it from building up and causing water hammer.

You should install pressure relief valves at strategic points in your pipeline, such as near the pumps and valves. Make sure that you choose the right pressure relief valve for your system, with the correct pressure setting.

6. Consider Using Air Chambers

Air chambers are small chambers that are installed in the pipeline. They contain a cushion of air that can absorb the pressure waves created by water hammer. When the pressure in the pipeline increases, the air in the chamber is compressed, reducing the pressure in the pipeline.

However, air chambers need to be maintained properly. Over time, the air in the chamber can dissolve in the water, reducing its effectiveness. You may need to periodically recharge the air chamber to keep it working properly.

Other Special Material Valves

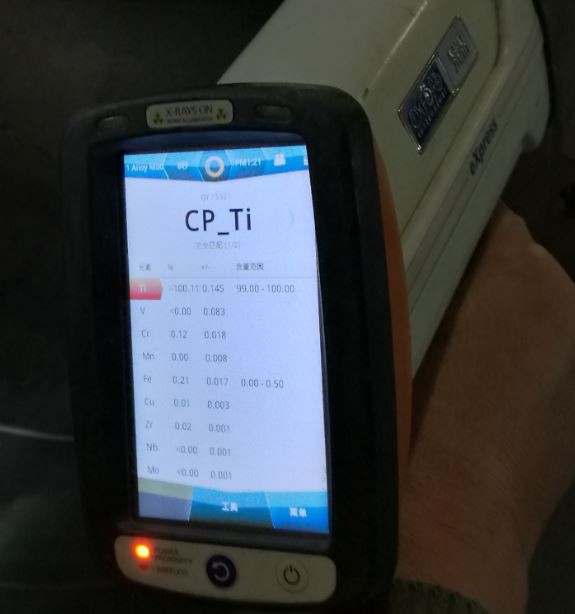

If you're looking for other types of special material valves, we also offer Titanium Valve, Hastelloy Valve, and Inconel Valve. These valves also have their own unique properties and are suitable for different applications.

Titanium valves are known for their extremely high corrosion resistance, especially in aggressive environments. Hastelloy valves are resistant to a wide range of corrosive chemicals and are often used in chemical processing applications. Inconel valves have excellent high-temperature strength and oxidation resistance, making them suitable for high-temperature applications.

Contact Us for Your Valve Needs

If you're facing water hammer issues in your Monel valve system or if you're looking for high-quality Monel valves or other special material valves, don't hesitate to contact us. We have a team of experts who can help you choose the right valves for your application and provide you with all the support you need.

Whether you need advice on preventing water hammer or you're ready to make a purchase, we're here to assist you. Reach out to us, and let's work together to ensure the smooth operation of your system.

References

- "Handbook of Valves" by Valve Manufacturers Association

- "Fluid Mechanics for Engineers" by some well - known fluid mechanics author (can't remember the exact one right now)

- Various industry reports on valve performance and water hammer prevention.