Hey there! As a safety valve supplier, I know firsthand how crucial it is to ensure the reliability of these life - saving devices. Safety valves are the unsung heroes in many industrial processes, preventing over - pressure situations that could lead to catastrophic failures. So, let's dive into how we can make sure they always work as they should.

1. Quality Manufacturing

First off, the foundation of a reliable safety valve lies in its manufacturing. We use top - notch materials. For example, when making the valve body, we opt for high - grade stainless steel or forged carbon steel. These materials can withstand high pressures and harsh chemical environments.

The manufacturing process is also tightly controlled. We have strict quality control measures at every step. From casting and machining to assembly, each stage is inspected thoroughly. Our machinists are highly skilled, and they use state - of the - art equipment to ensure that every part of the valve meets the exact specifications.

2. Precise Design

A well - designed safety valve is key to its reliability. The design has to take into account various factors like the operating pressure, temperature, and the type of fluid or gas it will be handling.

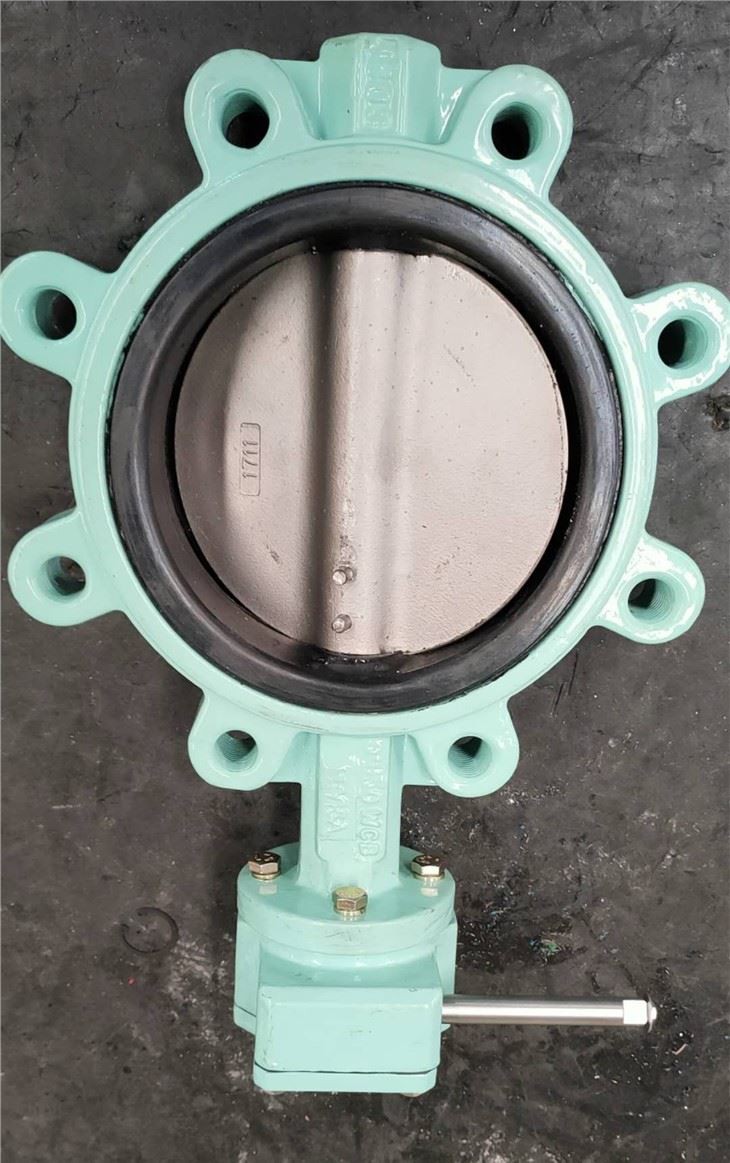

We've got different types of safety valves to suit different needs. For instance, our Floating Seat Bi - directional All - metal Seal Triple Offset Butterfly Valves Series 4200 are great for applications where tight shut - off and bi - directional flow are required. These valves are designed with a unique triple - offset mechanism that reduces wear and tear on the sealing surfaces, which in turn increases their reliability.

Another popular option is our Triple Offset Butterfly Valve Series 3000. The detailed design in the series 3000 catalogue shows how it's engineered to provide excellent performance in high - pressure and high - temperature environments.

3. Regular Testing

Testing is a non - negotiable part of ensuring reliability. Before a safety valve leaves our factory, it goes through a series of rigorous tests. We perform hydrostatic tests to check for leaks under pressure. The valve is filled with a liquid, usually water, and then pressurized to a level higher than its normal operating pressure. If there are any leaks, we can detect them right away and fix the issue.

We also conduct dynamic tests to simulate real - world operating conditions. These tests involve opening and closing the valve multiple times to make sure it functions smoothly and accurately. Only after passing all these tests do we consider a valve ready for the market.

4. Installation and Maintenance

Even the best - made safety valve won't work reliably if it's not installed correctly. That's why we provide detailed installation instructions with every valve. Our team can also offer on - site installation support if needed.

Regular maintenance is equally important. We recommend that our customers have their safety valves inspected and serviced at least once a year. During maintenance, we check the valve's components for wear, clean the internal parts, and replace any worn - out seals or gaskets.

For example, our Centerl Line Butterfly Valve has a relatively simple design, but proper maintenance is still essential to keep it in top - notch condition.

5. Staff Training

The people who operate and maintain the safety valves also play a big role in ensuring reliability. That's why we offer training programs for our customers' staff. These programs cover everything from basic valve operation to advanced troubleshooting.

By training the staff, we make sure that they understand how the safety valves work, how to perform routine checks, and what to do in case of an emergency. This knowledge can go a long way in preventing valve failures and ensuring the safety of the entire industrial process.

6. Documentation and Traceability

We keep detailed documentation for every safety valve we produce. This includes information about the materials used, the manufacturing process, the test results, and the installation and maintenance history.

This documentation is not only useful for us but also for our customers. It provides them with a clear picture of the valve's life cycle and helps them make informed decisions about maintenance and replacement. Traceability also allows us to quickly identify and address any issues that may arise.

7. Continuous Improvement

The world of safety valves is constantly evolving. New materials, technologies, and standards are emerging all the time. That's why we're committed to continuous improvement.

We invest in research and development to come up with better - designed valves that are more reliable and efficient. We also keep an eye on industry trends and regulatory changes to make sure our products always meet or exceed the latest requirements.

Why Choose Our Safety Valves?

When you choose our safety valves, you're not just getting a product. You're getting a comprehensive solution that includes high - quality manufacturing, precise design, thorough testing, and excellent after - sales support.

Our valves are designed to provide long - term reliability, which means fewer breakdowns and less downtime for your operations. We understand that in many industries, the cost of a valve failure can be extremely high, both in terms of financial losses and potential safety hazards. That's why we go the extra mile to ensure the reliability of our safety valves.

If you're in the market for a reliable safety valve, don't hesitate to reach out. Whether you need a valve for a small - scale operation or a large industrial plant, we've got the right solution for you. Contact us today to start a discussion about your specific requirements and how our safety valves can meet them.

References

- Industrial Valve Handbook: A Guide to Valve Selection, Design, and Application.

- ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 - Pressure Vessels.

- API 520 and API 526 Standards for Pressure - Relieving Devices.