Hey there! As a supplier of Inconel Valve, I've been getting a lot of questions about the creep - rupture properties of these valves. So, I thought I'd write this blog to share some insights.

What is Creep - Rupture?

Before we dive into the creep - rupture properties of Inconel Valve, let's quickly understand what creep - rupture is. Creep is the slow, progressive deformation of a material under a constant load over time. Rupture, on the other hand, is the failure of the material when it can no longer withstand the load. Creep - rupture, then, is the combination of these two processes. It's a crucial consideration when dealing with materials that are used in high - temperature and high - stress environments, like Inconel Valves.

Why Inconel Valves?

Inconel is a family of austenitic nickel - chromium - based superalloys. These alloys are known for their excellent corrosion resistance, high - temperature strength, and oxidation resistance. That's why Inconel Valves are widely used in industries such as aerospace, chemical processing, and power generation, where components are exposed to extreme conditions.

Creep - Rupture Properties of Inconel Valves

High - Temperature Resistance

One of the key creep - rupture properties of Inconel Valves is their ability to maintain their strength at high temperatures. Inconel alloys can withstand temperatures up to 1200°C (2192°F) without significant loss of strength. This is due to the formation of a stable oxide layer on the surface of the alloy, which protects it from further oxidation and degradation.

For example, in a chemical processing plant, where valves are often exposed to high - temperature corrosive fluids, Inconel Valves can operate reliably for long periods. The high - temperature resistance ensures that the valves don't deform or rupture under the constant stress of the flowing fluid.

Excellent Creep Strength

Inconel alloys have excellent creep strength, which means they can resist deformation over time under a constant load. The unique microstructure of Inconel, with its fine - grained structure and the presence of strengthening elements like titanium and aluminum, contributes to its high creep strength.

In aerospace applications, where valves need to withstand high pressures and temperatures during flight, the excellent creep strength of Inconel Valves is a must. It ensures that the valves maintain their shape and functionality, even under the demanding conditions of space travel.

Long - Term Stability

Inconel Valves offer long - term stability in creep - rupture situations. The alloys are designed to resist the effects of time - dependent deformation, which means they can maintain their integrity over extended periods. This is especially important in industries where downtime for valve replacement can be costly.

In a power generation plant, for instance, Inconel Valves can operate continuously for years without significant creep - rupture issues. This long - term stability reduces maintenance costs and improves the overall efficiency of the plant.

Comparison with Other Special - Material Valves

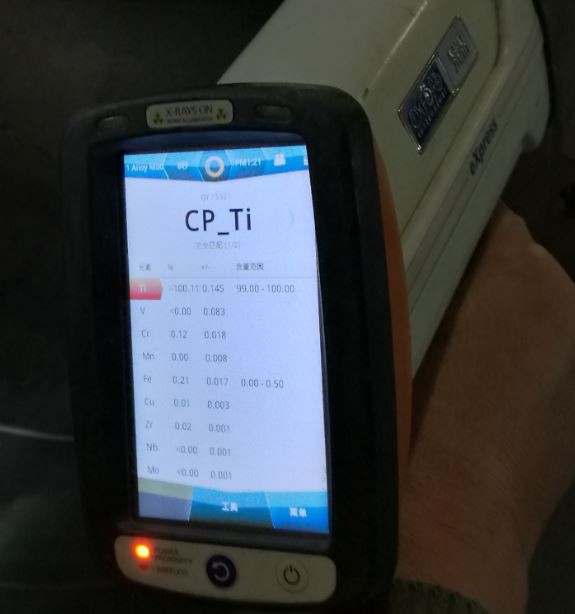

Titanium Valve

Titanium Valves are also popular in many industries due to their high strength - to - weight ratio and good corrosion resistance. However, when it comes to high - temperature creep - rupture properties, Inconel Valves have an edge. Titanium has a lower melting point and may experience more significant creep deformation at high temperatures compared to Inconel.

Zirconium Valve

Zirconium Valves are known for their excellent corrosion resistance in certain environments. But in terms of creep - rupture strength at high temperatures, Inconel Valves are often a better choice. Zirconium may not be able to withstand the same level of stress and temperature for as long as Inconel without experiencing creep - rupture.

Factors Affecting Creep - Rupture Properties

Temperature

The temperature has a significant impact on the creep - rupture properties of Inconel Valves. As the temperature increases, the rate of creep deformation also increases. That's why it's crucial to select the right Inconel alloy for the specific temperature range of the application.

Stress Level

The stress level applied to the valve is another important factor. Higher stress levels will accelerate the creep - rupture process. Engineers need to carefully calculate the stress levels in the system to ensure that the Inconel Valves can handle them without premature failure.

Alloy Composition

The composition of the Inconel alloy used in the valve also affects its creep - rupture properties. Different alloys have different amounts of elements like nickel, chromium, titanium, and aluminum, which can influence the strength, corrosion resistance, and creep behavior of the valve.

How We Ensure Quality Creep - Rupture Performance

As a Inconel Valve supplier, we take several steps to ensure that our valves have excellent creep - rupture properties.

Material Selection

We carefully select the Inconel alloys based on the specific requirements of the application. We consider factors such as temperature, stress level, and corrosion environment to choose the most suitable alloy.

Manufacturing Process

Our manufacturing process is designed to optimize the microstructure of the Inconel alloy. We use advanced techniques like hot forging and heat treatment to ensure that the valves have the right grain size and distribution, which contributes to their high creep - rupture strength.

Quality Control

We have a strict quality control system in place. Every valve undergoes rigorous testing, including creep - rupture testing, to ensure that it meets the highest standards. We also provide detailed documentation of the test results to our customers.

Conclusion

In conclusion, the creep - rupture properties of Inconel Valves make them an excellent choice for applications in high - temperature and high - stress environments. Their high - temperature resistance, excellent creep strength, and long - term stability set them apart from other special - material valves.

If you're in need of reliable valves for your industry, whether it's aerospace, chemical processing, or power generation, consider Inconel Valves. We're here to provide you with high - quality products and excellent service. If you have any questions or want to discuss your specific requirements, don't hesitate to get in touch for a procurement洽谈.

References

- ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High - Performance Alloys

- Metals Handbook: Properties and Selection: Nonferrous Alloys and Pure Metals